Cooking and eating

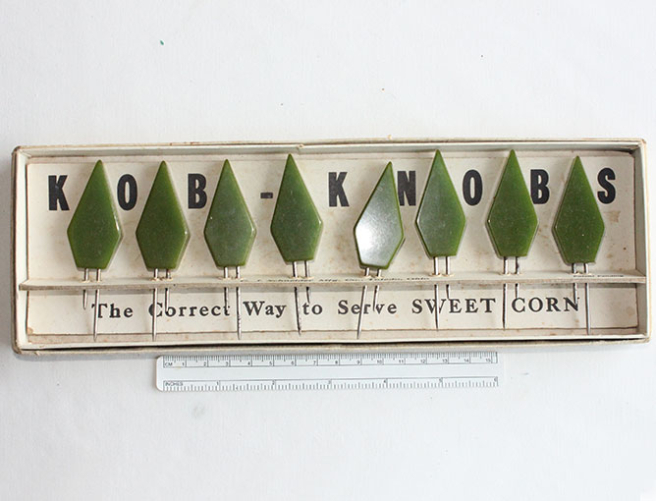

In the twenties and thirties electric power reached more and more households and the demand for consumer goods increased. New technological knowledge made it possible to start production on a much larger scale than before. Bakelite therefore was a very suitable material. The material in powder form could be poured into molds and bakelite products could be manufactured in mass production. Large-scale production made products also a lot cheaper and therefore accessible to many more people. During that time industrial design also takes off in an enormous way.

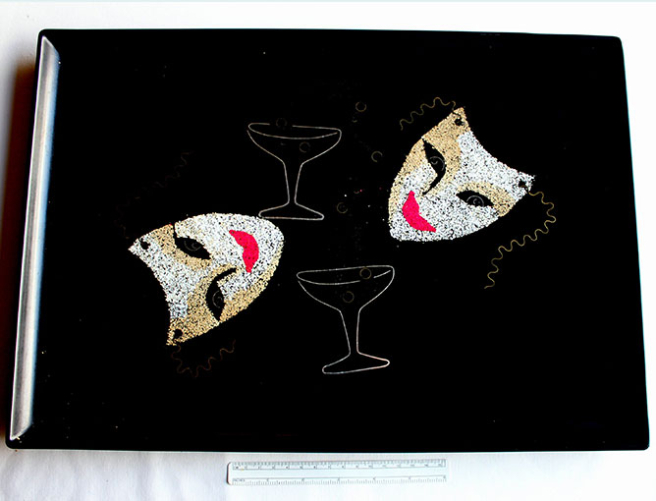

Couroc and handcrafted parquetry

The Couroc Plastic Company in San Francisco focused after World War II on the production of plates and service trays made of bakelite with handmade parquetry. The products were inlaid with copper, coral, marble and other materials. The business named after a descendant of the Courvoisier cognac family closed around 1990. The Couroc plates and service trays are still sought after by collectors.

Cleaning, heating and cooling

In the 1930s the breakthrough of electricity in the home resulted into a peak in the development and mass production of household electrical appliances. These devices saved time and made domestic work easier, as servants were disappearing in many households.

Bakelite was widely used in the production of these new devices. Bakelite vacuum cleaners, fans, irons, mixers and heaters conquered the market.

Clocks

Because bakelite is much more malleable than natural hard materials and cheap to produce, designers embraced this material and came up with the most diverse objects. From clocks, radios, bowls and boxes, to buttons and jewellery.

Jaz

Many clocks were made from 1930 on using a bakelite case. Many of these clocks are in Art Deco style. In the thirties and forties of the last century the French company Jaz made a series of stylish clocks that were largely made of bakelite.